The complete pipework system for fuel

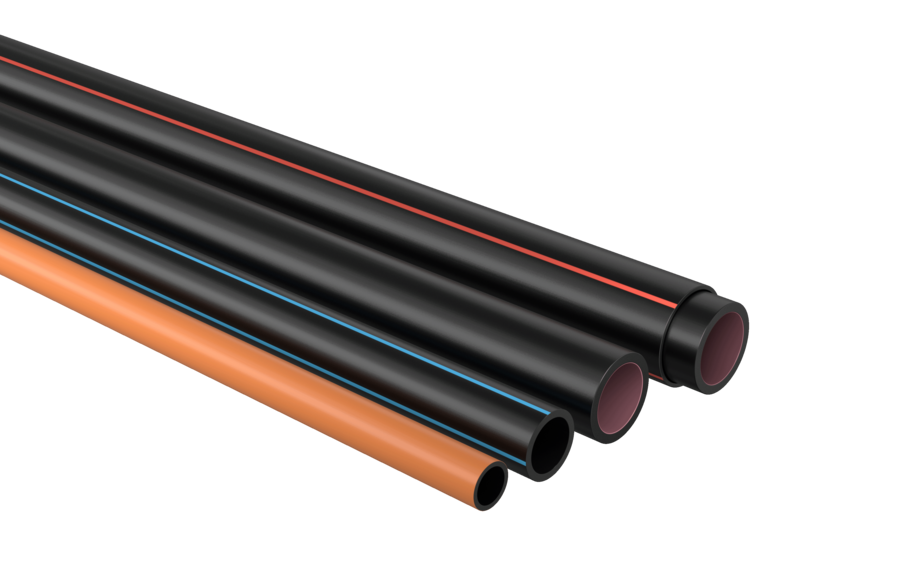

PLX is a complete range of specialist welded pipework systems for the safe transfer of fuels and their vapours.

PLX is suitable for use with traditional fuels such as leaded and unleaded petroleum and diesel, as well as alternative fuels such as bio-diesel, E10, E85 and a range of other fuel oils. PLX provides a specialist solution for fuel transfer across a variety of applications including forecourts, back-up power generators, rail, marine and off-grid power.

A multi-layered polyethylene composite pipe system offering an internal permeation barrier, PLX is available in both single-wall and secondary-contained options, and is specifically designed to provide maximum permeation protection to the environment. PLX is fully compliant with the Energy Institute (Institute of Performance Systems) and conforms to EN14125 regulations.

Through continuous innovation over 25 years, PLX offers a range of system options each tailored for specific applications in conveying fuels and their vapours.

System overview

- Single-wall and secondary-contained options

- Excellent lifetime cost savings vs traditional materials

- Leak detection capability (secondary containment)

- Maximised flow rates

- Efficient electrofusion installation process

- Innovative One-Weld fitting technology

- Solutions for AdBlue and forecourt cable protection

- Wide range of dedicated tooling

- Sizes 32mm to 160mm

- 30 year design life

- EN14125 approved

PLX single-wall

PLX single-wall is a multi-layered polyethylene composite pipe system featuring an internal permeation barrier, offering environmental protection into fuelling applications and approved to the requirements of EN14125. PLX single-wall pipe is accompanied by a fully matched range of electrofusion fittings and transition pieces offering a complete system for the safe transfer of fuels and their vapours. PLX single-wall pipework is commonly used for below ground applications for vent and vapour recovery lines.

- Maximised flow rates and excellent lifetime cost savings over traditional materials

- Efficient electrofusion installation process

- 10 bar (SDR11) or 6 bar (SDR17) pressure rating

- Available in 6m straight lengths, and 50m or 100m coils

- Sizes 32mm to 315mm

- 30 year design life

- EN14125 approved

PLX secondary contained close-fit

PLX close-fit pipework comprises a co-extruded polyethylene multi-layer primary pipe offering maximum permeation protection within fuelling applications, along with a secondary containment pipe which provides additional security against accidental fuel leaks or losses. The secondary pipe features ribs on the bore of the pipe ensuring the primary pipe is always centralised within the system. PLX close-fit is commonly used below and above ground within forecourts, emergency/back-up power generators, industrial refuelling and off-grid power.

- Compact installation solution

- Fully matched range of secondary-contained electrofusion fittings

- Unique "one-weld" fittings saving significant time in installation

- Ability to monitor for leak detection requirements

- Available in 6-metre straight lengths, and 50m or 100m coils

- 10 bar (primary pipe), 4 bar (secondary pipe) pressure ratings

- Sizes 32#40mm to 110#125mm

- 30 year design life

- EN14125 approved

One-Weld couplers

Our new range of electrofusion PLX fittings have been designed to significantly improve installation time on site. PLX One-Weld reduces the amount of pipe preparation time required and allows both the primary and secondary joints to be welded simultaneously in one weld cycle.

- 4 welds within one electrofusion cycle

- Saving significant installation time (average 15 minutes per fitting)

- Designed for use with PLX secondary contained close fit pipe

- Manual and barcode welding options

- Industry first One-Weld elbow

Termination fittings

Designed to enable PLX secondary contained close fit pipe to be terminated to a single wall connection all within one fitting, while maintaining secondary containment throughout the pipeline. Reducing the number of preparation steps, fittings and welding sequences required over traditional termination assemblies.

- Reduces the amount of time and parts required during installation

- Designed for use with PLX secondary contained close fit pipe

- Compact design vs traditional methods

- Interstitial monitoring options

- Adheres to Blue Book recommendations

PLX secondary-contained large diameter

PLX secondary-contained system offers a pipe-in-pipe solution for larger diameters within industrial fuelling applications. The primary polyethylene pipe has an internal permeation barrier specifically designed to offer maximum environmental protection, and is held centrally by spacers to a secondary pipe offering environmental protection in the event of a leak. PLX secondary-contained is used for above and below ground applications in bulk transport refuelling applications such as rail and marine where high volumes of fuel are transported from tank to dispenser.

- Offers peace of mind with leak detection access fittings

- Complete with secondary-contained electrofusion fittings

- Available in 6-metre straight lengths

- 10 bar (primary pipe), 4 bar (secondary pipe) pressure rating

- Sizes 160#225mm to 315#400mm

- 30 year design life

- EN14125 approved

PLX blue

PLX blue is a specialist pipework system dedicated to the transfer of AdBlue within forecourt and other industrial transport applications, both above and below ground. With the ever-increasing use of AdBlue to lower NOx concentrations in the exhaust emissions of diesel engines, a high quality pipework system is required to convey the solution from tank to dispenser. PLX AdBlue has been designed to offer corrosion resistance, maintained flow rates and an efficient installation process, offering peace of mind over the lifetime of the system.

- Available in both single-wall and close-fit options

- Fully matched electrofusion jointing for ease of installation

- Duplex stainless steel transition fittings for connecting to existing systems

- Maximum flexibility and corrosion resistance

- Excellent lifetime cost savings

- 10 bar pressure rating (primary pipe)

- Sizes 32mm (single-wall) and 32#40mm (close-fit)

PLX electrical conduit

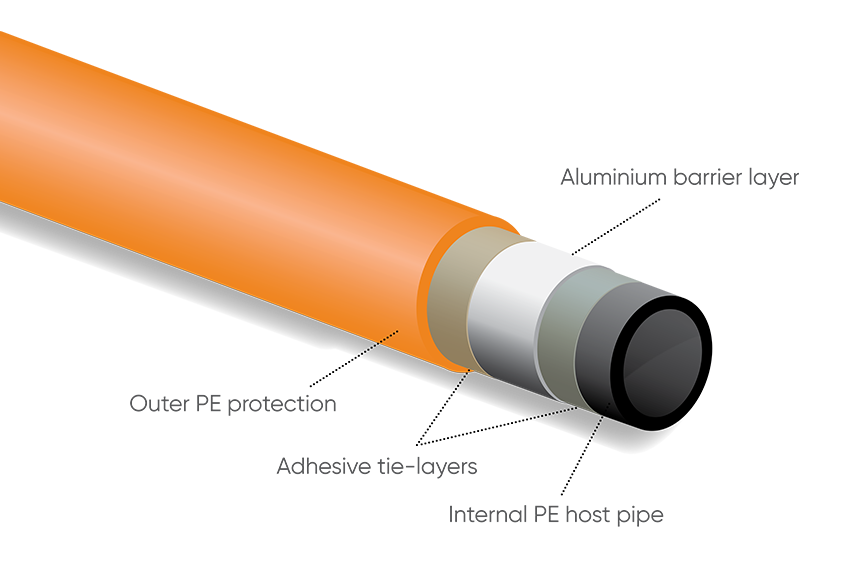

With a true permeation barrier, PLX electrical conduit offers a unique solution for protecting cables from potential fuel spillages and leaks within forecourt applications. Unlike internal barrier alternatives, PLX electrical conduit is specifically designed to prevent any fuel from entering the pipework from the external environment. The conduit has been designed with a unique double-bonded five-layer construction, comprising an internal black polyethylene (PE) host pipe, an impermeable aluminium barrier layer which stops the ingress of any contaminants that may be present in the ground, and an outer orange PE protection layer, along with two adhesive tie layers.

- Unique aluminium external permeation barrier

- Choice of fitting options: compression (Philmac) and PLX electrofusion

- Efficient installation process

- Rigid construction reduces movement during installation

- Supplied in 100m coils

- Size 32mm single-wall as standard (other sizes are available)

- Approved to the mechanical requirements of AS/NZS 61386.1.2015

PLX tooling

PLX has a dedicated range of tooling options to ensure the safest and most efficient installation possible. All of the tooling in the range is specifically designed for use with PLX systems.

- Electrofusion control units and accessories

- Pipe clamps for single-wall and secondary-contained pipes

- Pipe preparation kits including hand scrapers, pipe cutters and isopropanol wipes